From "Hand Milling" to "Almighty King": Technical Evolution of Vertical Machining Center and China's Power

In the heart of modern factories, you often see such a scene: a machine tool with compact shape and precise structure, running at high speed with a low buzz. Its spindle, like a tireless dancer, draws an accurate trajectory on the metal blank, drilling, milling and tapping in one go, and finally turns out smooth and complicated parts. This machine is the "universal machine tool" of manufacturing industry-vertical machining center.

It does not appear out of thin air, but is the crystallization of industrial evolution and market tempering after more than half a century. Today, when we talk about the transformation from "Made in China" to "Made in China", the development track of vertical machining center is the most vivid footnote of this grand narrative.

First, the road to evolution: from manual operation to digital soul

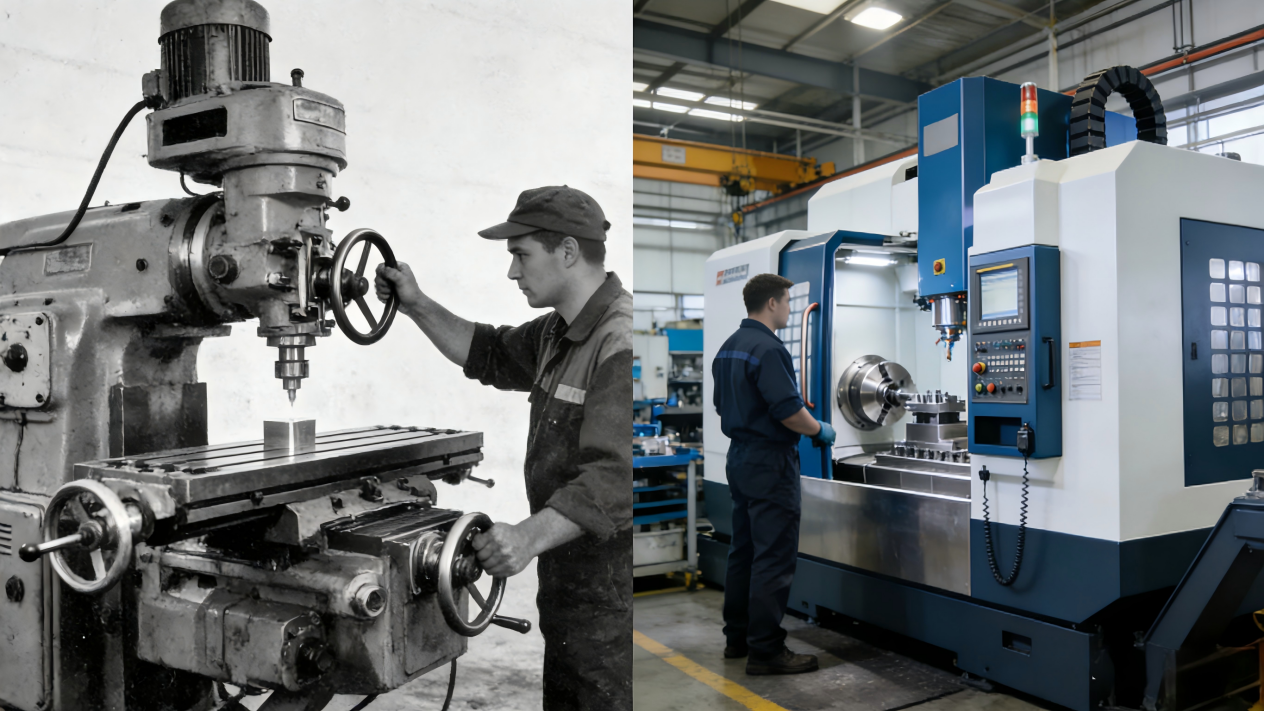

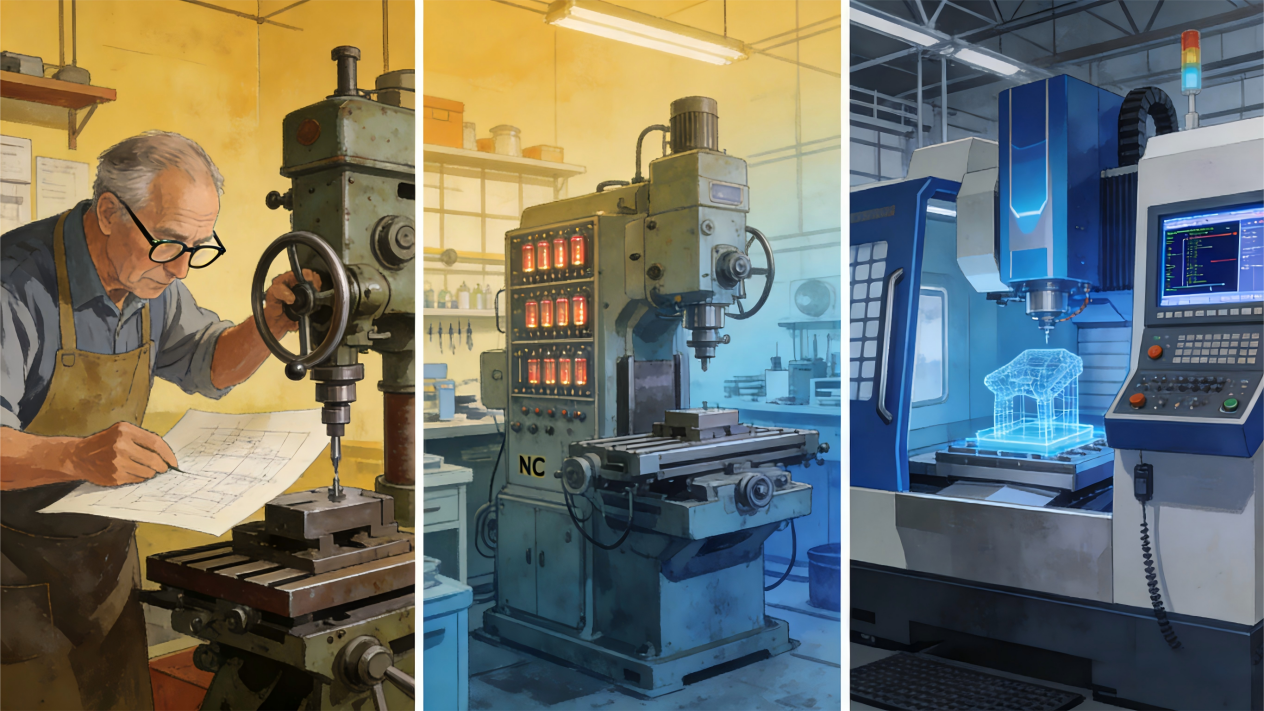

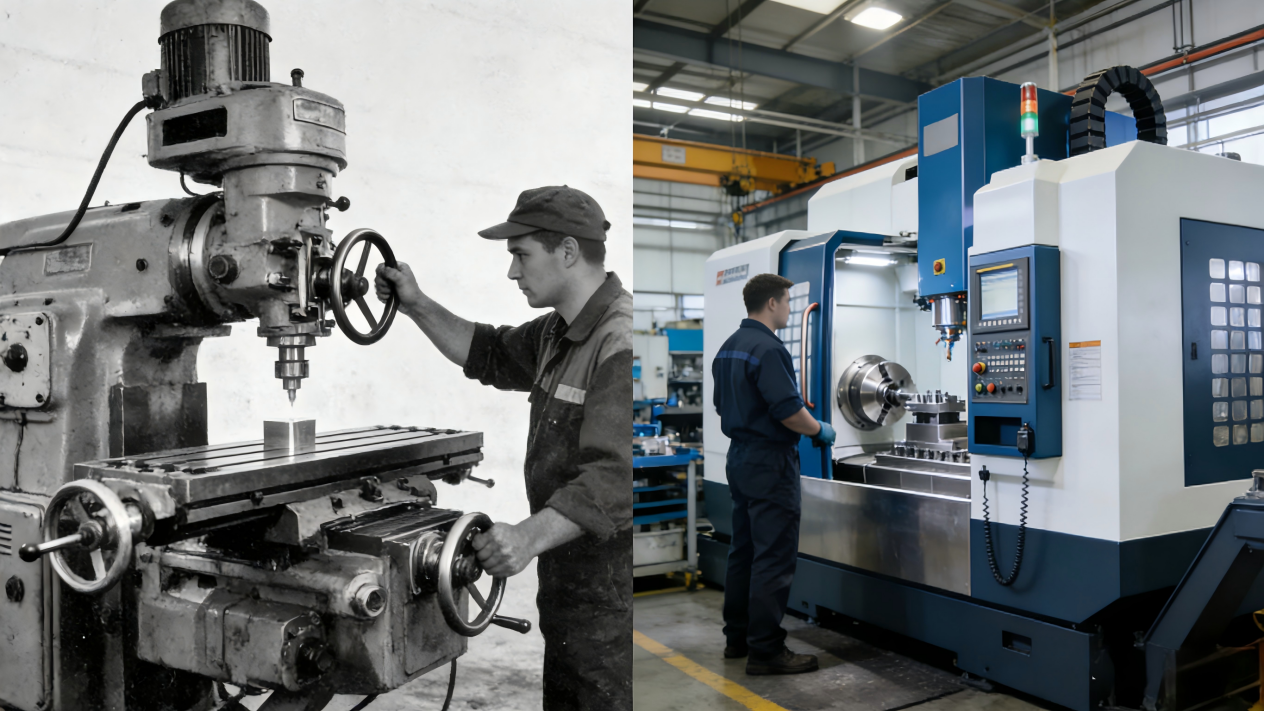

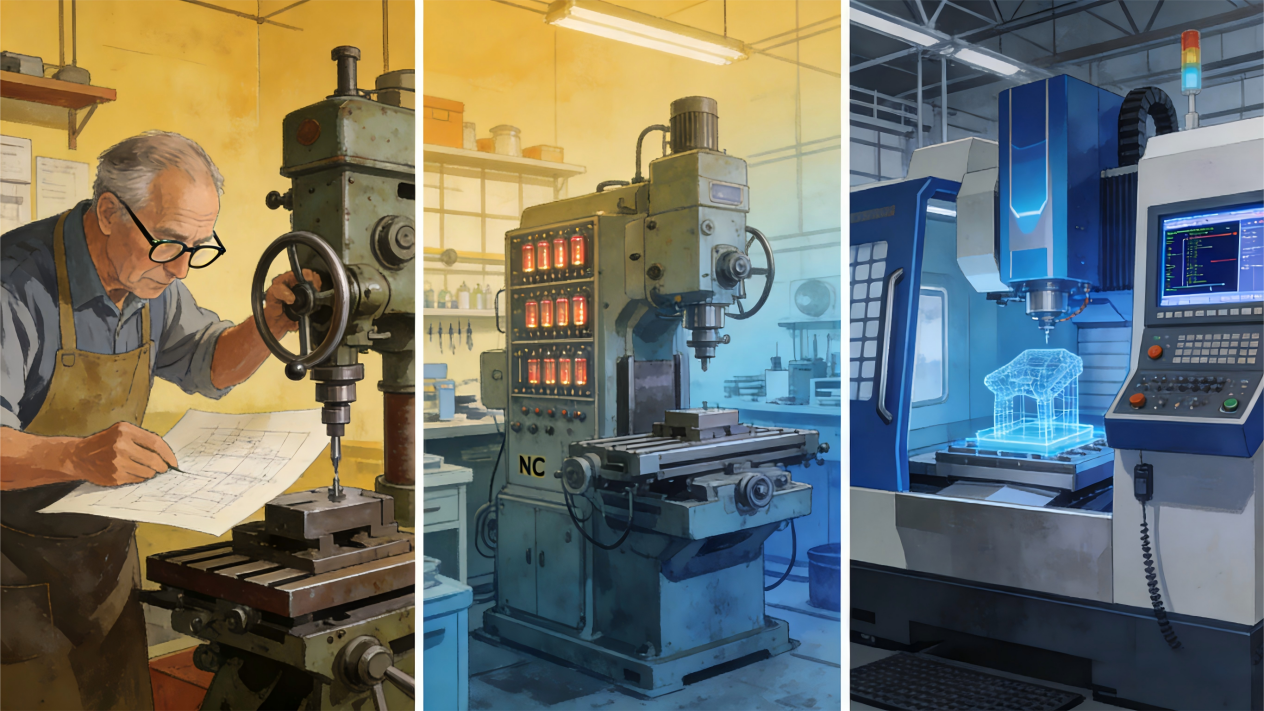

1. The "feel" and bottlenecks in the traditional era

Before the birth of numerical control technology, machining was highly dependent on "craftsmanship". Operators need to manually shake the handwheel of the milling machine to control every inch of movement of the cutter. In the face of complex curves and surfaces, it is often necessary to draw them with the help of templates, templates, or experience, and the accuracy and efficiency are difficult to guarantee. Especially for the complex parts with many varieties and small batches needed in aerospace, precision instruments and other fields, it is almost impossible to achieve large-scale and high-quality production by traditional methods.

2. Dawn of the digital revolution: the first CNC milling machine

The urgent demand for "high precision, high efficiency and high automation" in manufacturing industry has given birth to revolutionary technology. In 1952, Massachusetts Institute of Technology cooperated with Parsons Company to successfully develop the world's first three-coordinate CNC milling machine. For the first time, it converts the information such as the shape and size of parts into digital instructions, and drives the tool to move through electronic control devices. Although the control device of this equipment is huge and filled with more than 2000 electron tubes, it marks a new era of numerical control in mechanical manufacturing.

3. The birth of a master: a modern machining center

The CNC milling machine solves the problem of "automatic control", but it still needs manual frequent tool replacement after one clamping. In 1958, a machining center with automatic tool changer (ATC) came out, which truly realized the centralization and automation of working procedures. Especially the vertical machining center, because of its compact structure, convenient clamping and easy observation, has quickly become the main force in the processing of medium and small complex parts (such as molds, plates and disk sets).

The core of this evolutionary chain is the continuous upgrading of the "brain". From the early numerical control (NC) that relied on hardware to the computer numerical control (CNC) that introduced microprocessor in the 1970s, and now to the intelligent system that integrates artificial intelligence and Internet of Things, the control system of machine tools has changed from a "rigid instruction executor" to an "intelligent terminal that can think and optimize".

Second, dissect the "Almighty King": the dispute between core architecture and motivation

A modern vertical machining center is a precise integration of machinery, electricity, software and sensing technology. Its core subsystems include numerical control system (brain), servo drive and motor (limbs), spindle system (heart), tool magazine and automatic tool changer (weapon magazine), and basic structures (bones) such as lathe bed and guide rail. Among them, the spindle is the "heart" that directly performs cutting, and its driving mode directly determines the performance boundary of the machine tool.

There are two main transmission modes with the highest penetration rate on the market:

Note: Although linear motor drive has the outstanding advantages of high speed and high precision, it is only used in a few ultra-high speed and ultra-high precision machine tools at present because of its extremely high cost, and has not yet become the mainstream in popular vertical machining centers.

There is no absolute winner behind this "power struggle", only the most suitable choice. Machine tool manufacturers choose different "heart" schemes according to the processing requirements of the target market (heavy cutting or high finish), cost positioning and their own technical accumulation.

Third, the power of industrial agglomeration: reshaping the password of China machine tool "model"

To understand the diversity of China vertical machining center market, we must go deep into the industrial soil on which it depends. A notable feature of China's manufacturing industry is industrial cluster. According to statistics, the Yangtze River Delta, Pearl River Delta and Bohai Rim have contributed 75% of the national machine tool production capacity. These clusters are not only a collection of factories, but also the formation of a complete supply chain ecosystem, which has given birth to highly differentiated machine tool demand and model fission.

For example, in Wenling, Zhejiang, Ningbo and other places, dense industrial clusters of molds, plastic products and small hardware have been formed. The factory here needs to deal with a large number of parts with relatively simple structure but requiring rapid delivery every day. This gives birth to a huge demand for three-axis vertical machining centers with high cost performance, durable leather and simple operation. The localization of the supply chain enables the machine tool factory to obtain lathe bed castings, sheet metal casings, standard rails, screws and other parts at extremely low cost and extremely fast speed. As a result, a large number of "economical" VMC series models optimized for these markets have been developed and produced. They may not pursue extreme accuracy, but they definitely pursue the ultimate cost control and stability.

A more extreme case comes from the consumer electronics industry cluster in Kunshan, Jiangsu. There is a complete electronic information industry chain here, and its processing demand is extremely clear: most parts are aluminum alloy, with complex structure, extremely high precision requirements, and huge production batch, and the pursuit of processing efficiency reaches the extreme. The traditional general vertical machining center is "heavy" here, and its advantage (heavy cutting) is not the core requirement. As a result, a more professional and extreme subdivision category-drilling and attacking center has become the absolute king here.

Drilling and tapping center is a deep specialization of vertical machining center to meet the requirements of "quickness, accuracy and agility", and its comparison with general VMC is as follows:

This type fission caused by "industrial agglomeration-supply chain matching-demand differentiation" is the source of vitality and complexity of China machine tool market. It explains why there are both "machine tools" with affordable prices and special models tailored for specific industries.

Fourth, the choice of market: the evolution and coexistence of guide rails

In the history of vertical machining center, the choice of guide rail clearly reflects the comprehensive trade-off between efficiency, accuracy, rigidity and cost in different application scenarios.

Linear guide (ball or roller guide) has become the absolute mainstream. Its friction coefficient is extremely small, allowing the machine tool to realize high-speed and high-acceleration movement (such as fast moving 48 m/min); The precision is guaranteed by the guide rail manufacturer, which can be replaced after wear, and the precision life is predictable and maintainable. This is a great advantage in today's pursuit of production rhythm and flexible manufacturing.

However, the hard rail (steel-inlaid guide rail or plastic-stuck guide rail) has not disappeared, and its high rigidity, strong vibration resistance and heavy load capacity are still the first choice for heavy cutting and rough machining. The real change in the market lies in the refinement of configuration: the pure "three hard rails" machine tools are reduced because of the difficulty in maintenance and the slow moving speed; The more popular scheme is "two lines and one hard"-hard rail is used in the X axis (or Z axis) which bears the main cutting force to ensure rigidity, and wire rail is used in the fast-moving Y axis to ensure speed.

Behind the market changes: the upgrading of supply chain services is an important driving force. Nowadays, material suppliers generally provide pre-roughing service, and the die steel blanks purchased by customers are close to the net size, which reduces the need for long-term and large-margin roughing of machine tools. At the same time, the machining of cavity parts such as injection mold is really concentrated on vertical milling (Z-axis action), and the lateral force is relatively stable. Under this working condition, the configuration of "two wires and one hard" not only retains the rigid advantage of hard rail on the key stress surface, but also improves the overall speed and maintainability through the wire rail, and only needs to pay attention to the wear and maintenance of a single hard rail surface, thus becoming a golden scheme of "die machine" with high cost performance.

V. Response of Kunshan Duyang: Dealing with the pluralistic era with professional genes and strict technology.

Kunshan Duyang CNC Machine Tool Equipment Co., Ltd. (abbreviated as Duyang CNC), which grew up in Kunshan, a hot spot of manufacturing, has a profound understanding of this. The company is located in Kunshan Precision Mould Intelligent Manufacturing Zone, which is a CNC machine tool manufacturing enterprise integrating R&D, production, sales and service. Since its establishment in 2017, we have been deeply rooted in local industrial clusters, with product lines covering vertical machining centers, high-speed drilling and tapping machines, gantry machining centers, etc., and accurately serving core fields such as 3C electronics, automobile manufacturing and mold processing.

Faced with such a diversified, layered and rapidly evolving market, we know that the soul of a good machine tool begins with design and ends with manufacturing. The core members of our founding team are all from industry benchmark enterprises, and they are well versed in the design essence and technological know-how of high-stability machine tools. But this is just the beginning. Real Excellence is born in every detail from the source of casting to the final factory.

1. Abide by the process: do not save electricity or cost, but only seek value.

In order to fulfill the promise of "making more valuable machine tools", Duyang CNC adheres to almost paranoid rigor in every link of the manufacturing chain:

Casting foundation: We insist on optimizing resin sand castings cast by Yunnan high-quality primary iron ore. Its internal metallographic structure is denser, and after long-term natural and artificial aging treatment, the stress is fully released, which physically ensures the eternity of geometric accuracy of the bed under long-term heavy load and cold and hot changes.

Assembly soul: The core assembly and debugging process is led by the master with more than ten years or even decades of experience. With the feeling of fingertips and the sound in their ears, they can match the accuracy of micron level. This "craftsman's touch", which can't be programmed simply, is the key to a stable soul for machine tools.

Closed-loop inspection: each machine tool must pass 26 special quality inspection procedures covering dimensions such as basic structure, motion accuracy and cutting performance. This is not a simple process record, but a complete quality closed loop, ensuring that problems are found in time and zeroed.

Ex-factory domestication: all machine tools have to go through a continuous half-day water test and a three-day heavy-duty running-in before leaving the factory. This simulates the most severe working conditions, and the purpose is not to "test" but to "domesticate"-to make all parts reach the best matching state before leaving the factory, and to ensure that customers take over a stable and reliable mature equipment, rather than a "semi-finished product" that needs running-in.

2. Product matrix: accurately match market segments

Based on the above rigorous manufacturing system, Duyang CNC has formed a clear product matrix to meet the processing challenges of different industries:

Conclusion: Take root and climb with precision.

From meeting the efficiency peak of 3C industry to overcoming the structural problems of new energy industry, the evolution of machine tools has always been driven by industrial demand. The story of Kunshan Duyang is a microcosm of active participation and deep roots in this grand history. We draw the most advanced insight from industrial agglomeration, forge the most reliable bones and muscles in strict technology, and finally transform the simple concept of "making more valuable machine tools" into deterministic productivity that customers can rely on in both traditional and emerging tracks.

We are convinced that the next climb of China's manufacturing industry must belong to those enterprises that deeply understand the industry, adhere to the essence of manufacturing, and can accurately transform technology into customer value. Duyang CNC is willing to work together with upstream and downstream partners to reach a new height of "China Precision" with professional genes and practical experience in Kunshan.