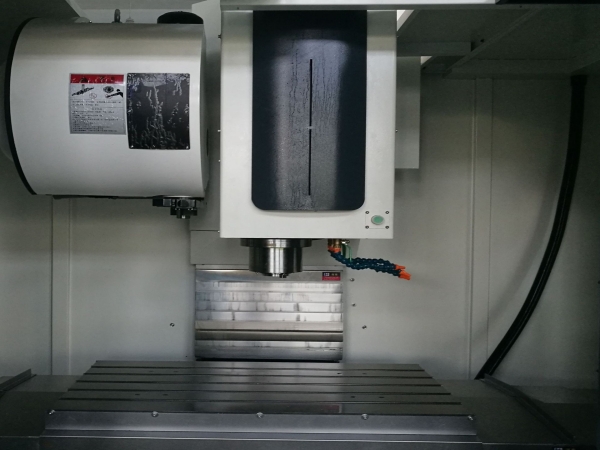

DY-850B machine configuration:

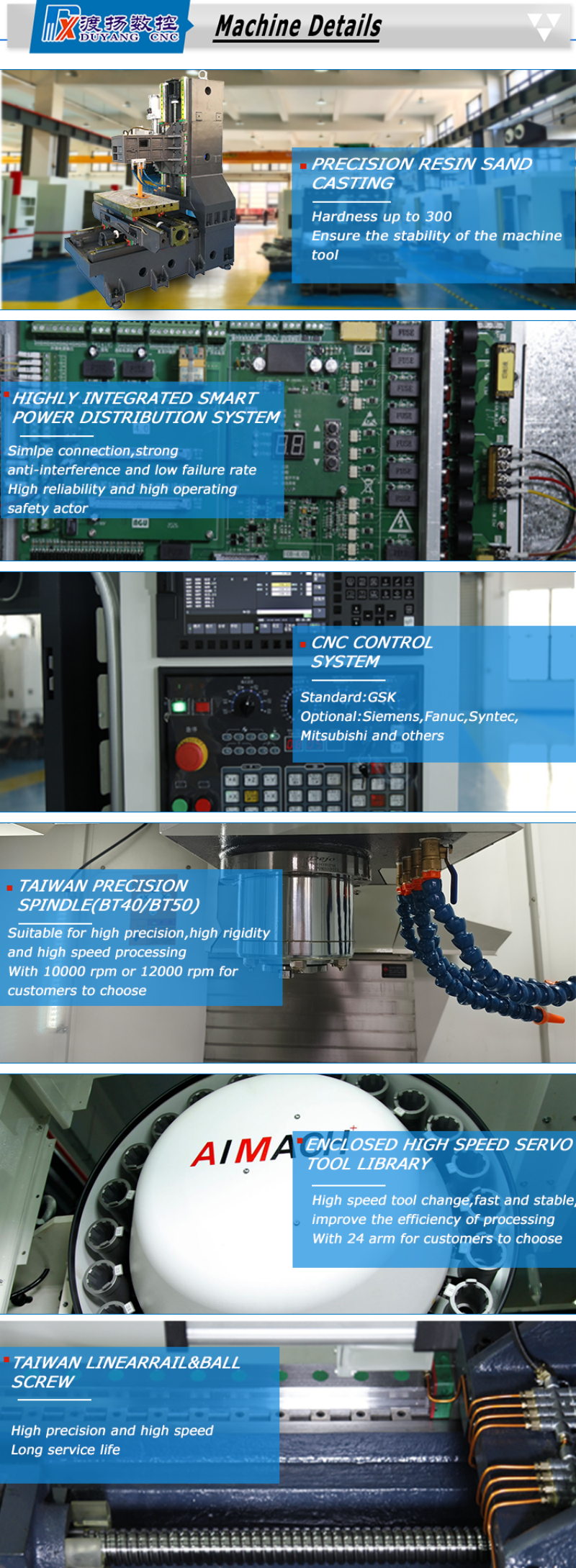

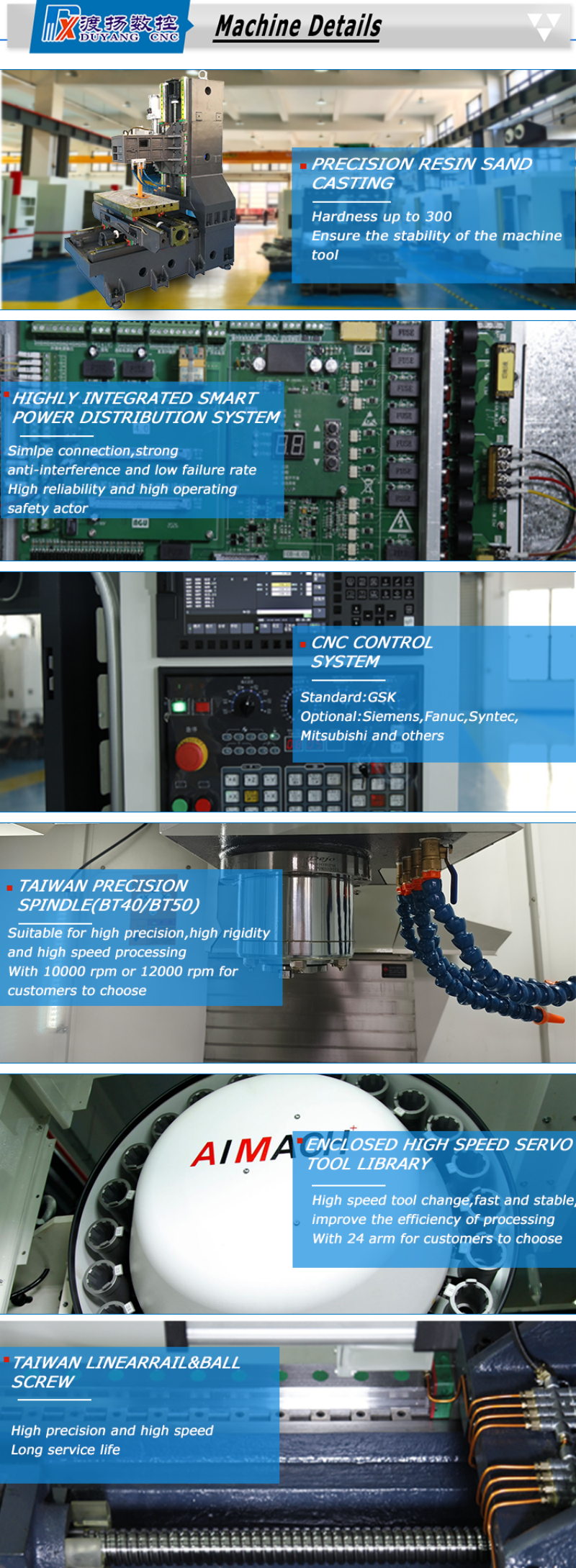

1, control system: Japan FANUC-0I-MF digital control system (optional Japan Mitsubishi M80 system, Central system).

2. Three-axis drive motor: full digital servo motor.

3, spindle motor: full digital servo spindle motor.

4, spindle: Taiwan Luo Yi/National Taiwan University/Jian Chun/Aibeke/Dejiu direct coupling spindle 12000 rpm.

5, automatic lubrication and lubrication alarm device: HERG (River Valley)/Shengxiang/Bechir.

6, ball screw: Taiwan Silver/Yintai, precision ball screw, C3 level.

7, booster cylinder: Taiwan Hao Cheng or Zhen Zhen.

8, bearing: Japan NSK, P4 level.

9. Electric cabinet: electric cabinet heat exchange constant temperature system.

10. Hand pulse: Japanese handheld electronic hand pulse.

11, coupling: Germany R+W or S+J.

12, cooling pump: Duyang.

13, body: resin sand precision body.

14. Tool library: Taiwan Desu/Beiju BT40-24T disk tool library.

15. Spindle oil cooling: Diot.

16, random data: operation programming milling machine, diagnostic instructions, machine tool instructions, packing list.

Note: 1. If you need special configuration, please contact the technical service telephone, and specify in the order when ordering;

2. The Company is conducting research and improvement work at any time, so it reserves the right to change the technical parameters of the optical machine at any time, without prior notice.

After-sales Service:

1 Installation and commissioning

1).The buyer shall provide the eguipment installation site and make preparations according to the matters notified by the Supplier in advance.

2).After the equipment arrives at the factory, conduct unpacking inspection with our company's representative. If any damage or reduction is found, please inform our company immediately.

3).After unpacking and acceptance of the equipment, the Buyer shall first conduct mechanical positioning, cement filling of foundation holes, rough level adjustment and other works, and then fine installation adjustment. The Buyer shall at least notify our company to send personnel in advance.

4). The Buyer is requested to assist the installation and commissioning personnel of our company in arranging accommodation, meals and transportation, etc.

5).The Buyer is requested to designate the operator and maintenance personnel of the machine, and assign special personnel to assist our company in the installation and commissioning of the machine tool. After the mechanical acceptance is completed, the buyer shall sign the machine tool acceptance report in duplicate in real time, and each party shall keep one copy.

2 Acceptance

1). Before installation acceptance, the Buyer shall prepare for installation and commissioning according to installation and commissioning matters.

2).Appearance inspection: The personnel of the Buyer and the Seller shall conduct visual inspection on the appearance, and check and accept according to the Contract and its annexes.

3).Performance and function acceptance: Acceptance shall be carried out according to the scope of supply of machinery and controller determined by both parties.

4).Mechanical accuracy acceptance: The acceptance shall be based on the inspection record sheet of random delivery accuracy provided by our company.

3 Technical training

1)The Supplier shall be responsible for technical training for the Demander, and the training time, place and content shall be based on the contract agreed by both parties (the training time can be conducted during installation and commissioning).

2)The training content is related to the actual project, and the training shall be conducted on the machinery, system, operation, maintenance and other related contents.

4.4 Quality service

1)From the date of final acceptance, 12 months'Three-Guarantee service shall be implemented for the whole product, and free maintenance shall be implemented for the product within the warranty period (only cost fee shall be charged for vulnerable parts, man-made damage and force majeure).

2) During the warranty period, if it is verified that it is the user's fault: The appearance or internal damage of the machinery caused by the loading and unloading and transportation process and the storage time is too long; the human damage caused by improper operation and self-disassembly and modification shall not be covered by the above free warranty, and the user must pay all maintenance and repair expenses. (Note: The damage of equipment caused by natural disasters is not covered by our company's warranty. For example:lightning strike, flood, fire, earthquake, as well as relocation, secondary training, etc.).

3)If the equipment fails and the user information is obtained, the cause and treatment measures of the failure can be accurately judged, the reply shall be given immediately;if the reply cannot be given immediately, reply within 2 hours, and send personnel to the site for treatment as soon as possible. The specific time depends on the preparation time of parts.

4)After the warranty period expires, our company will continue to provide maintenance services for users, and collect the cost of parts and service fees according to our charging standards.

5) If the Buyer fails to perform according to the Contract afteracceptance, the Seller shall have the right to stop after-sales service.

Due to the different configuration, special order, numerical control system and continuous optimization of products, some technical parameters will be affected. Please check according to the actual situation when ordering, and the supply and sales contract shall prevail!In the actual application of the Technical Agreement, the Supplier has the responsibility and obligation to optimize the application of the principle of being responsible for the customer.